|

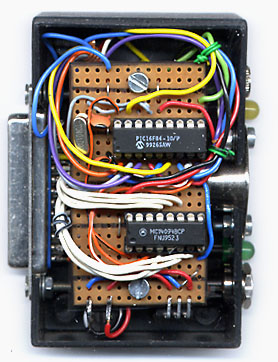

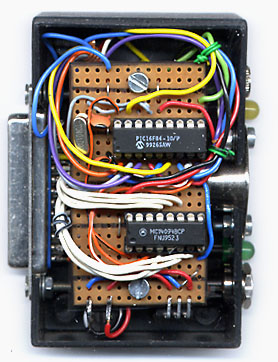

[12/10/99] Finally got the TMW boxed. The box will have a see through cover

for the curious visitors to see at Turku Exchibition 30th--31st Oct. 1999.

During fitting found some cold joints from the relay card. Perhaps the

programming will work better after re-soldering!

Olli installed DCC-connectors for feeding the DCC underneath the baseboards.

We used crimp connectors and 15-pin D-connectors: The 15-pin D-plug will short

all sidings etc. feeders into one, so that the power routing turnouts will be bridged.

If we want to use conventional power (no DCC), removal of the plugs will get

us back to old sysytem (power routing turnouts).

Opa (one of our members) has fitted old

Arnold decoders we have got (Thanks Lars!) to our Dm7 rail cars (Swedish Y6 models

repainted by Tomppa, another member of the club).

[31/10/99] Exhibited the setup at Turku exhibition. Operated the TMW for two six-hour

sessions with very little problems. The feature we were not aware of was that the

throttles are inoperative while keying in assignment commands. We also experienced

a peculiar problem due to too weak a power supply (Roco starter set transformer!):

when the internal overload cut-out started to intermittedly cut out power of the

transformer we succed in brown-out'ing the PIC in such a state that all locos switched

to dc. This kind of situation should not happen if the TMWDCC is assembled correctly

and fed directly with a power supply of correct capacity. If we would have operated the

TMWDCC with the latest version of software the emergency halt would have halted

the trains as it now also operates the relays of the relay card!

As the above incident happened at the same time as one of the operators had

his mobile phone ringing, we for a while suspected a radio frequency error, but

that was clearly ruled out as the operators did make calls to each other with the

mobile phones kept delibrately close to layout and moving trains. As the local

newspaper mentioned our stand to have the most advanced technology in the exhibition

(old 8086 PC?), the boys got an idea while I was away having a meal (they told me

this after the exhibition was colsed):

While another operator was running a loco from behind, the other operator came close

to the loco and, with his Nokia Communicator open, acted as if he was operating the

loco with it -- the first TMWDCC-WAP connection ;)

[07/11/99] In the morning I went to the Old Toy Swap (arranged by Marklin Club

of Finland) and bought two old Märklin transformers for the TMWDCC, went to

the club and retuned the Ackdetector with resistor in relay card and relying

on the LED's installed to the Ack detector output. I'm now able to read all

the decoders we have: Old Arnold, Roco, Lenz and Probst!

I also managed to install the latest (1.31) version of TMW software. All looks

great now!

[07/12/99] Helsinki MRC Xmas exhibition is behind. All in all TMWDCC operated

well. We had some problems with our emergency buttons, but those will be solved.

We are also still having a cold joint somewhere, as we are unable to connect

throttle #4 to the system (this is clearly our fault, not the system fault!)

[09/12/99] Finally found the misconnected wires of throttle#4! Noted that Emergency

halt is also inoperative during command keying. Must get the Emergency halt

to directly operate the main relay!

We still wish to get the disconnected throttle loco assignments visible on screen,

and possibility of assigning locos to disconnected throttles.

[25/04/00] The Model-Expo-2000 exhibition lasted four days, total of 30 hours of

running. TMWDCC was operational all the time, and didn't need any booting or

special attention during exhibition.

As it was impossible to change functions or see the assignments of disconnected

throttles the operators got somewhat irritated. Occasionally someone went to change

the assignments during running without warning others and this caused nuisance

(but these are features of TMWDCC).

The younger boys enjoyed the freedom of DCC too much: we had two full speed head on

collisions within five minutes! The lack of forced dicipline of the DCC in general

caused the older members to long for the old system of no DCC!

[05/07/00] Got ver 1.33 beta from Lars for trial run: Ah what Joy!

The screen now displays the loco assignments of disconnected throttles.

A faster method for typing in assignments has also being introduced

(not exactly to my liking but close enough).

We tried the "reverse DC" operation with one loco [LE103XF: CV29.2=0 and CV50.2=1].

We installed a DPDT switch to the wires between layout and booster so that with the

switch we could switch the layout into ordinary DC power pack.

The DC power pack was set into full reverse and the switch was flipped while the

loco was travelling under DCC: The loco in came into halt according to the

braking rate. We then switched back to DCC and the loco speeded at acceleration

rate set into decoder.

I understand that this feature only works with decoders built strictly according

to RP 9.2.4.

I'm being adviced that those decoders that don't follow this rule [and that are

therefore not fully NMRA-DCC compatible] are designed to give better dc operation

at low speed and pulsed power, as the processor need not take any action in dc mode.

As Tapiola presently uses solely Lenz decoders (home made decoders have not proven

to be satisfactory or worth the trouble!) we could exploit this feature.

TMWDCC throttles

This is the first test throttle: 100k potentiometer and a switch connected

directly to D15 connector. Four throttles should be possible to be connected

to a single game controller card (speed control potentiometers in place of

joystick potentiometers and direction switches in place of fire buttons).

Maximum of 8 throttles should be possible to be connected using two game

controller cards (the other card must be modified to change the port address).

A separate bus will be fitted with RJ-45 receptacles for throttles.

[24/05/99] There is a ghost throttle #5 although only throttle #1 is connected.

This should fix when the other game port card is installed

[25/05/99] Altered the above throttle from type-A to be a type-C throttle.

Works ok. To select loco number needs some practice! Capable of switching

lights on and off from Roco receiver (five pushes of button while loco is

in motion -- fun!)

[01/06/99] Un-assigning a loco from (any) throttle and then re-assigning it

to throttle #9 (keyboard) causes the loco to halt. If throttle #9 speed is

adjusted the loco jumps to correct speed. Re-assignment to other throttles

works normally.

[10/08/99] Olli and Teppo (our members) got the trottle bus panels made and Lauri

(yet another member of our club) got four throttles assembled! After

some errors with soldering the cables (my mistakes!) we were able to get the

first RJ-connected throttle (cab) to be connected to throttle positions

1...4. We added an emergency halt button to RJ-socket panels just to be on the

safe side, but as the boxed TMWDCC sitill has the throttle bus connectors

not internally connected the emergency button is inoperative!!!.

[07/11/99] Unassigned trains will now surely halt at emergency too, as the latest

version (1.31) of TMW software also operates the relay after three---five

seconds after activating emergency halt, so there will be no runaway trains!

[01/12/99] Olli got the throttle bus connectors inside the TMWDCC box

connected so that we have the emergency halt buttons of the throttle panels

operating. The throttle position #4 is still unoperating, propably due to

a cold joint somewhere.

[09/12/99] Found the misconnected wires of throttle #4! Noted that Emergency

halt is also inoperative during command keying. Must get the Emergency halt

to directly operate the main relay! Throttle #9 is now with 1.32 software reset to

zero at Emegency -- great!

[22/12/99] Finally found a "matching pair" of gameport adapters: After the

boys manage to solder the missing wires of the second quad RJ-panels of the

throttle panels, we'll be able to use all eight sockets. Presently we have

a slight problem with selecting of the functions with type-C throttle, but

no doubt that will be settled soon.

[27/07/99] By changing the throttle bus capacitors from 200uF to 10uF we

got the functions working with the present joystick cards! The screen now

displays the loco assignments of disconnected throttles.

[05/07/00] Got ver 1.33 beta from Lars for trial run: Ah what Joy!

The screen now displays the loco assignments of disconnected throttles.

[09/04/02] First test drive with a selfmade IR throttle! IR-throttles are

under development/construction. We seem to be in a need of wireless

throttles as during exhibitions all throttle cables are usually tied

into a spagetti knot as operators move between front station and fiddle yard

at the rear of the layout.

Development strted a few months ago, and first actual throttle

is complete, the second one waits for transfer from patchboard to Vero

board. I hope to have two IR-throttles in use at Model-Expo 2002 in Helsinki

Icehall in a few weeks time. The project is based on RC5 type bit formation

but bits are shorter and message presently only consists of single

start bit, 8 bit payload and parity bit. Throttles and receiver are built

around PIC16F84 at 4 MHz, transmitters are LD271 at approx. 1 ampere and

receivers are TSOP1738 modules. This is a very barebones system, designed for

max. four throttles. The development material (not final!) may be found at

here.

[27/04/02] We have now used the first IR-throttle for two days in Model-Expo.

The throttle performs as expected. I have today assembled the second throttle

and we'll test the use of two throttles tomorrow at last day of the exhibition.

[28/04/02] Exhibition over, the system worked well, and will be developed further.

[20/08/02] Got the first proto of MkII IR-throttle! The club is about to attend

a show were we were given unlimited space, so we try to put all our modules in a

row (something like 30 metres (100ft) of modules. It would be quite unpractical

to walk to the middle of the layout just to change the loco you wish to operate,

so a mechanism was deviced that allows change of RJ-45 patch cables electronically

through the throttle. Software's now patched but not polished.

[09/09/02] Have now assembled most of the hardware to do the socket change. The vero

board is fully populated, and I need to make some piggyback chips to save space and

to avoid chaining dozens of chips on the vero board. This is no more fun...

[01/10/02] Have returned from holiday, and have come up with an idea of combining

the IR receiver and PC into a single PIC chip. During holiday tried to figure out

how to combine the DCC signal timing (needs attention every 58us) and the IR signal

timing (needs attention at unpredictable moment and then at 416us interval). The

code seems to become too complicated for me, so opted to use the TMWDCC

hardware, so that the DCC data is sent in 8 bit chunks at approx 900us rate -- yes!

[04/10/02] First successful test run of "PC-eliminator" — i.e. the MkIII IR-throttle!

[08/02/03] The PC-eliminator was running during the

XX National Model Railway Days 2002 16th-17th Nov.2002

We wished a location by the wall, but instead we were placed in the middle of the hall

with walls and roof far away. We used 8 IR-receivers and got fair operation.

The Helsinki MRC's Xmas exhibition was better,

as the layout perimeter was smaller. We had two Roco cranes in operation. One of

the IR-throttles developed a fault during the first day of the show (It refused to

change address). The fault presisted allthough the processor was changed. We have now

erected the layout to the club and I hope to be able to search for the remedy the

problem of this one throttle.

[28/04/03] Last weekend was the Model-Expo show in the old Helsinki Ice Hall. We operated

the three day show with PC-Eliminator and TMWDCC hardware. I havent yet sent the faulty

Lenz LE103FX decoders to Lenz for repair (need the extra capacitor next to zener), so

we were guaranteed to have some runaway trains. the above mentioned throttle not changing

address was fixed (adjusted the speed pot trimmer). It seems that the system is forgetting the

addresses of locos or something as we quite often had to reset the locos by keeping

them off the metals (tilt) for a few seconds. I plan to modify the PC-eliminator

code so that it will display the addresses of cabs in sequence if nothing more

pressing is to be displayed so as to make sure the addresses aren't lost during running!

[24/11/03] I have now upgraded the PC-eliminator software so that is not allowing loco

(address) capture in case the previous owner has the speed in non-zero position (diplay

shows "Err!").

Apparently this is not enough, as we are still experiencing the need to re-press the address

selector due to throttle loosing control. I have now included a double packet check into

software, but commented it out as it seemed too slow (ther must be two identical commands from

individual throttle before the action is taken). I'll investigate further, probably it should

be selective so that only direction change and address change would be double checked.

I also realized a design fault: The speed pot is read so that the greater the resistance

the faster the loco goes. As the tracks of pots get worn out we get (or got!) an uncontrollable

situation. Not nice!

Antti has some rotary encoders, and I'm going to look into possibility of replacing the pots

with encoders. Also, I think we'll need button type throttles as well, as those are excellent

in trying to get the youngsters into driving more carefully.

The display now shows in sequence the address, speed and functions settings of throttles in case

no-one is sending any IR-packets. As the amount of packets during operating session is so great

the display is of no use during ordinary running. I think that the display should in fact only

show the sequential data and not try to display everything (the eye cannot catch individual

commands from flashing display).

See Tillorps

Mekaniska Werkstad for complete description of TMWDCC by Lars Lundgren.

|

![Schematic diagram of modified Probst decoder [4K]](./../../../img/project/dcc/probst_1.gif)

![Schematic diagram of modified Probst decoder Mk II [4K]](./../../../img/project/dcc/probst_2.gif)